Safety measures when operating construction trucks are crucial for protecting workers, the public, and the environment. These vehicles are powerful and potentially dangerous, requiring careful attention to detail and adherence to strict safety protocols. From pre-shift inspections to emergency procedures, every step in the operation of a construction truck demands a commitment to safety.

This guide provides a comprehensive overview of essential safety measures, covering topics such as pre-shift inspections, safe driving practices, load management, working safely around trucks, emergency procedures, and the importance of personal protective equipment. By understanding and implementing these measures, we can significantly reduce the risk of accidents and create a safer work environment for everyone involved.

Pre-Shift Inspection and Preparation: Safety Measures When Operating Construction Trucks

A thorough pre-shift inspection is crucial for ensuring the safe operation of construction trucks. It helps identify potential hazards and mechanical issues that could lead to accidents or breakdowns.

Importance of Pre-Shift Inspections

A pre-shift inspection is a fundamental safety practice that helps prevent accidents and ensure the safe operation of construction trucks. It allows operators to identify potential hazards and mechanical issues before they become critical, reducing the risk of breakdowns, injuries, and property damage.

Pre-Shift Inspection Checklist

A comprehensive pre-shift inspection checklist should include the following components:

Tires

- Check for tire pressure, tread depth, and any signs of damage, such as cuts, punctures, or bulges.

- Ensure all lug nuts are securely tightened.

- Inspect for uneven wear patterns, which could indicate alignment issues.

Brakes

- Test the brakes for responsiveness and effectiveness, ensuring they are not dragging or pulling to one side.

- Check for brake fluid leaks and ensure the fluid level is within the acceptable range.

- Inspect the brake pads or shoes for wear and tear.

Lights and Mirrors

- Verify that all headlights, taillights, brake lights, turn signals, and hazard lights are functioning correctly.

- Ensure all mirrors are clean and securely mounted, providing clear visibility in all directions.

- Inspect the windshield for cracks or damage that could obstruct the operator’s view.

Fluid Levels

- Check the engine oil, coolant, brake fluid, and power steering fluid levels. Ensure they are within the recommended ranges.

- Look for any signs of leaks or discoloration in the fluids, which could indicate a potential problem.

Other Components

- Inspect the engine compartment for leaks, loose connections, and unusual noises.

- Check the condition of the belts, hoses, and wiring.

- Ensure the horn, emergency brake, and all gauges are working properly.

- Verify that the load is properly secured and balanced.

- Check the condition of the truck’s body, including the chassis, bed, and any attachments.

Identifying and Addressing Potential Hazards

During the pre-shift inspection, operators should be aware of potential hazards and take appropriate steps to address them. For example:

- If a tire is low on pressure, it should be inflated to the correct level before operation.

- If a brake light is out, it should be repaired immediately.

- If a fluid level is low, it should be topped off with the appropriate fluid.

- If any other mechanical issue is identified, it should be reported to the supervisor or maintenance personnel for immediate attention.

Remember: A pre-shift inspection is not just a formality. It is a critical safety practice that can help prevent accidents and ensure the safe operation of construction trucks.

Safe Operation of Construction Trucks

Operating construction trucks safely is paramount to preventing accidents and ensuring the well-being of workers and the public. This section focuses on essential safety practices during the operation of these heavy vehicles.

Traffic Laws and Regulations

Following traffic laws and regulations is crucial for the safe operation of construction trucks. These laws are designed to prevent accidents and ensure the smooth flow of traffic. Construction trucks, due to their size and weight, pose unique challenges to road safety.

- Speed Limits: Construction trucks must adhere to posted speed limits, which are often lower than those for regular vehicles. This is because their weight and size make it difficult to stop quickly.

- Weight Restrictions: Bridges and roads have weight restrictions to prevent structural damage. Construction trucks must comply with these restrictions, ensuring their loads do not exceed the specified limits.

- Lane Usage: Construction trucks may be restricted from using certain lanes, particularly those designated for high-speed traffic. Drivers must be aware of and follow these restrictions.

- Special Permits: In some cases, construction trucks may require special permits to operate on specific roads or during certain hours. Obtaining and adhering to these permits is crucial for legal and safe operation.

Safe Driving Practices

Safe driving practices are essential for operating construction trucks safely. These practices help to minimize the risk of accidents and ensure the safety of everyone on the road.

- Maintaining a Safe Distance: Construction trucks require a greater stopping distance than regular vehicles due to their weight and size. Drivers should maintain a safe distance from other vehicles to allow for adequate braking time.

- Using Turn Signals: Using turn signals clearly and well in advance is crucial for other drivers to anticipate the truck’s movements, especially when turning or changing lanes.

- Avoiding Distractions: Construction truck drivers must remain focused on the road at all times and avoid distractions such as cell phones, eating, or talking to passengers. Distracted driving significantly increases the risk of accidents.

- Being Aware of Blind Spots: Construction trucks have large blind spots, making it difficult for drivers to see vehicles or pedestrians around them. Drivers should use mirrors and check their blind spots frequently to ensure they are aware of their surroundings.

- Being Cautious in Adverse Weather Conditions: Driving in adverse weather conditions such as rain, snow, or fog requires extra caution. Drivers should reduce speed, increase following distances, and use headlights appropriately.

Backing Up and Maneuvering in Confined Spaces

Backing up and maneuvering construction trucks in confined spaces can be challenging and dangerous. These tasks require careful planning and execution to prevent accidents.

- Spotters: Using spotters is essential when backing up or maneuvering in confined spaces. Spotters can provide visual guidance to the driver, ensuring they are aware of any obstacles or pedestrians in their path.

- Backup Alarms: Construction trucks should be equipped with backup alarms to alert pedestrians and other vehicles of the truck’s movement. These alarms are crucial for preventing accidents, especially in crowded areas.

- Using Mirrors and Cameras: Drivers should use mirrors and backup cameras to get a clear view of their surroundings when backing up. This helps them to identify potential hazards and avoid collisions.

- Slow and Controlled Movements: When backing up or maneuvering in confined spaces, drivers should move slowly and carefully. Sudden movements can lead to accidents.

- Avoiding Obstacles: Drivers should carefully assess the area before backing up or maneuvering, identifying any potential obstacles such as walls, poles, or other vehicles.

Load Management and Securing

Proper load management and securing techniques are crucial for ensuring the safety of construction workers, the public, and the transportation infrastructure. Failure to properly manage and secure loads can lead to serious accidents, injuries, and property damage.

Types of Loads and Securing Methods

The securing methods for different types of loads vary based on their size, weight, and characteristics. Here are some common types of loads and their appropriate securing methods:

- Bulk Materials: Materials like gravel, sand, and aggregates are often transported in dump trucks. These loads are secured using tarps, nets, or other coverings to prevent spillage during transport.

- Construction Equipment: Heavy equipment, such as excavators, bulldozers, and loaders, are typically transported on lowboy trailers. These loads require specialized securing methods, including chains, straps, and tie-downs, to prevent movement during transport.

- Precast Concrete: Precast concrete components, like beams, slabs, and walls, are often transported on flatbed trailers. These loads are secured using straps, chains, and blocks to prevent shifting and damage during transport.

- Steel Beams and Pipes: Steel beams and pipes are commonly transported on flatbed trailers. These loads are secured using chains, straps, and blocks to prevent movement and ensure stability during transport.

Risks Associated with Overloading or Improperly Securing Loads

Overloading or improperly securing loads can pose significant risks, including:

- Vehicle Instability: Overloading or improperly securing loads can cause the vehicle to become unstable, leading to rollovers or loss of control.

- Load Shifting: If loads are not properly secured, they can shift during transport, causing damage to the vehicle, cargo, and infrastructure.

- Spillage: Unsecured loads can spill, creating hazards for other drivers and pedestrians.

- Damage to Infrastructure: Overloaded or improperly secured loads can damage bridges, roads, and other infrastructure.

- Accidents and Injuries: Overloading or improperly securing loads can lead to accidents and injuries to workers, drivers, and the public.

Working Safely Around Construction Trucks

Construction trucks are an integral part of any construction project, but they also pose significant safety risks to workers on the site. Understanding and mitigating these risks is crucial to ensuring a safe working environment.

Common Hazards Associated with Working Around Construction Trucks

Construction trucks present various hazards to workers in their vicinity. These hazards can lead to serious injuries or fatalities if not properly addressed.

- Blind Spots: Large trucks have extensive blind spots, making it difficult for drivers to see workers, particularly those standing near the rear of the truck or on the passenger side.

- Truck Movement: Construction trucks often operate in tight spaces, making sudden movements or backing up hazardous. Workers may be caught unaware, leading to collisions.

- Loading and Unloading: The process of loading and unloading materials can involve heavy lifting and potential falling objects. Workers must be aware of these risks and take precautions.

- Spills and Leaks: Construction trucks may transport hazardous materials, and spills or leaks can pose significant health risks to workers.

- Noise and Vibration: Construction trucks generate considerable noise and vibration, which can contribute to hearing loss and other health problems.

Importance of Clear Communication and Signaling, Safety measures when operating construction trucks

Effective communication and signaling between workers and truck operators are essential to prevent accidents.

- Designated Hand Signals: Establish clear hand signals for communication between workers and truck operators, ensuring everyone understands their meaning.

- Two-Way Radios: Use two-way radios to communicate critical information, such as approaching trucks, potential hazards, or changes in work areas.

- Visibility: Workers should wear high-visibility clothing and use warning devices, such as cones or flags, to enhance their visibility to truck operators.

Safety Plan for Workers in the Vicinity of Construction Trucks

A comprehensive safety plan is crucial to minimize risks when working around construction trucks.

- Designated Walkways: Establish clearly marked walkways for workers to move around the site, ensuring they are separate from truck traffic areas.

- Safety Zones: Designate safe zones for workers to stand or work, ensuring they are located at a safe distance from moving trucks.

- Truck Spotters: Employ spotters to guide truck operators, ensuring they have a clear view of workers and potential obstacles.

- Regular Safety Meetings: Conduct regular safety meetings to reinforce safe practices and address any concerns regarding truck operations.

- Emergency Procedures: Develop and communicate clear emergency procedures in case of accidents or spills involving construction trucks.

Emergency Procedures

Emergencies can occur unexpectedly during construction truck operations. It is crucial for operators to be prepared and know how to respond effectively to ensure the safety of themselves, other workers, and the public. This section will Artikel essential emergency procedures, covering accident response, breakdown management, and contacting emergency services.

Emergency Response in Case of Accidents

Accidents can happen, and construction truck operators must be prepared to respond appropriately. The following steps are crucial in handling accidents:

- Prioritize Safety: The first and foremost priority is the safety of everyone involved. Secure the accident scene by activating hazard lights and placing warning cones or flares to alert other vehicles. If possible, move the truck to a safe location, but only if it can be done without risking further injury or damage.

- Assess Injuries: Check for injuries among those involved in the accident. If there are any injuries, call emergency services immediately. If trained in first aid, provide necessary assistance while waiting for paramedics.

- Gather Information: Collect as much information as possible about the accident, including the date, time, location, and any potential contributing factors. Note the names and contact information of any witnesses. This information will be essential for accident reporting and investigation.

- Contact Supervisor and Company: Inform your supervisor and the company’s safety manager about the accident. They will guide you on the necessary steps to follow, including reporting procedures and documentation.

Breakdown Management

Construction trucks are heavy-duty vehicles, but breakdowns can still occur. When a truck breaks down, it is essential to:

- Park Safely: Pull the truck off the road to a safe location, away from traffic and pedestrian areas. Engage the parking brake and activate hazard lights to alert other vehicles.

- Assess the Situation: Determine the nature of the breakdown. If it is a minor issue that can be addressed quickly, you may be able to resolve it yourself. If the breakdown is more serious, contact your supervisor or company for assistance.

- Contact Emergency Services: If the breakdown poses a safety hazard, such as a leaking fuel tank or a fire, contact emergency services immediately. Be prepared to provide them with the location of the breakdown and the nature of the problem.

- Document the Incident: Record the date, time, location, and details of the breakdown. Note any actions taken to address the problem and the names of any individuals involved. This documentation will be helpful for reporting purposes and potential future repairs.

Contacting Emergency Services

When contacting emergency services, it is essential to be clear and concise. Have the following information ready:

- Location: Provide the exact location of the incident, including street address, landmarks, or GPS coordinates.

- Nature of the Emergency: Explain the type of emergency, such as an accident, breakdown, or fire. Be specific about the situation and any potential hazards.

- Number of People Involved: Indicate the number of individuals involved in the incident, including any injuries.

- Contact Information: Provide your name, phone number, and any other relevant contact information. This will allow emergency services to reach you if necessary.

Safety Tips for Handling Emergencies

Here are some additional tips for handling emergencies safely and efficiently:

- Stay Calm: Panicking can lead to poor decision-making. Take a deep breath and try to remain calm. This will help you assess the situation clearly and respond effectively.

- Follow Safety Procedures: Adhere to the company’s emergency procedures and safety protocols. These procedures are designed to ensure the safety of everyone involved.

- Communicate Clearly: Communicate effectively with others involved in the emergency, including other workers, emergency services, and supervisors. Ensure everyone understands the situation and their roles.

- Be Aware of Your Surroundings: Pay attention to your surroundings and potential hazards. This will help you avoid further accidents or injuries.

- Document Everything: Keep detailed records of the incident, including any actions taken, observations made, and the names of individuals involved. This documentation will be essential for reporting purposes and future reference.

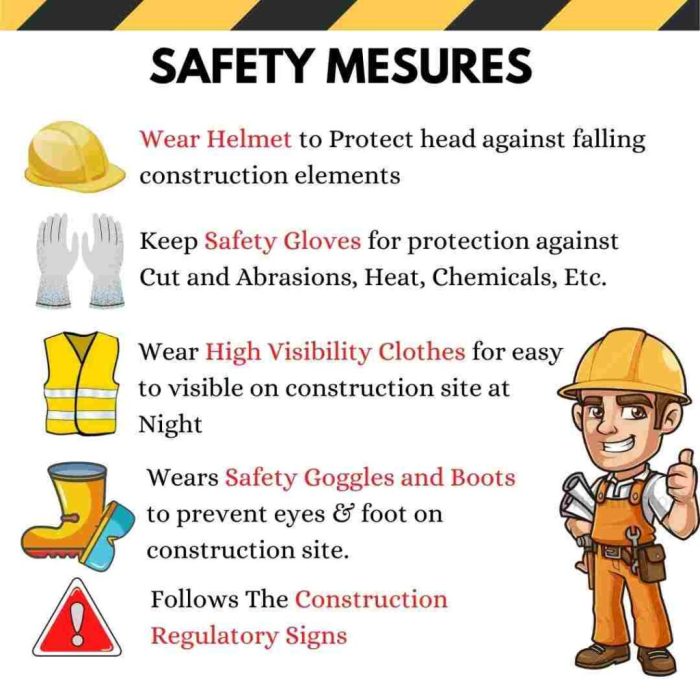

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is crucial for ensuring the safety of construction truck operators and those working around them. Wearing appropriate PPE can significantly reduce the risk of injuries from various hazards present on construction sites.

Essential PPE for Construction Truck Operators

The following items constitute essential PPE for construction truck operators:

- Hard Hats: Protect the head from falling objects, debris, and impacts.

- Safety Glasses: Shield the eyes from flying debris, dust, and harmful UV rays.

- Gloves: Protect hands from cuts, abrasions, and contact with hazardous materials.

- High-Visibility Clothing: Increases visibility to other workers and vehicles on the site, reducing the risk of accidents.

Importance of Wearing PPE

Wearing appropriate PPE at all times while operating or working around construction trucks is paramount for the following reasons:

- Protection from Injuries: PPE acts as a barrier against potential hazards, minimizing the severity of injuries in case of accidents.

- Compliance with Safety Regulations: Most construction sites have strict safety regulations that mandate the use of specific PPE for various tasks.

- Increased Awareness: High-visibility clothing enhances awareness of the operator’s presence on the site, reducing the risk of collisions with other vehicles or workers.

Situations Requiring Specific PPE

Specific situations on construction sites require the use of additional PPE:

- Working at Heights: When operating trucks on elevated platforms or slopes, fall protection equipment such as harnesses and lanyards are essential.

- Handling Hazardous Materials: When working with hazardous materials like chemicals or asbestos, specialized gloves, respirators, and protective clothing are required.

- Operating in Confined Spaces: When working in confined spaces, such as tunnels or trenches, additional PPE like respirators and safety harnesses may be needed.

End of Discussion

By following these safety measures, construction truck operators can contribute to a safer work environment for themselves, their colleagues, and the public. Remember, safety is not just a responsibility, but a shared commitment. A proactive approach to safety can save lives, prevent injuries, and ensure the smooth and efficient operation of construction projects.

Operating construction trucks safely is paramount, especially when hauling heavy loads of various materials. Understanding the properties of these materials, like concrete, steel, and wood, is crucial for safe handling. You can find a comprehensive overview of Types of construction materials used on this website.

By being aware of the weight distribution, potential hazards, and appropriate loading techniques for different materials, operators can significantly minimize risks and ensure a safe work environment.

Operating construction trucks safely requires a commitment to following established protocols, including regular vehicle inspections and driver training. These measures are crucial for ensuring the smooth and efficient progress of a project, just as quality control procedures in construction projects are essential for delivering a high-quality final product.

By upholding these standards, we create a safer work environment for everyone involved and contribute to the successful completion of the project.