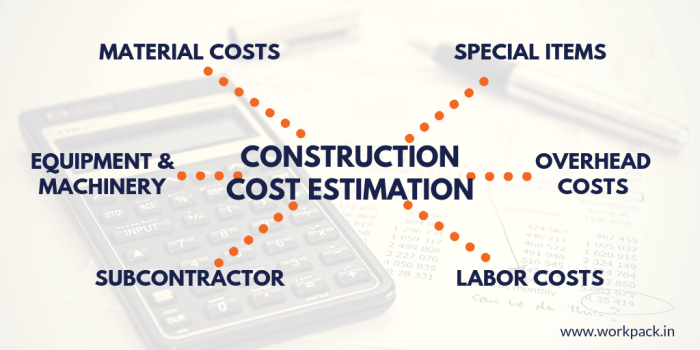

Cost estimation methods in construction industry play a crucial role in project success. From top-down to bottom-up approaches, these methods impact every aspect of a construction project. Let’s delve deeper into the world of cost estimation and explore the key factors that influence accurate estimates.

Overview of Cost Estimation Methods in Construction Industry

Accurate cost estimation is crucial in the construction industry as it helps in determining the budget required for a project, assessing the feasibility of a project, and ensuring that the project remains profitable. Poor cost estimation can lead to cost overruns, delays, and even project failure.

Different cost estimation methods impact project success in various ways. For example, using historical data and parametric estimating methods can provide a quick and rough estimate at the early stages of a project, helping in decision-making. On the other hand, detailed methods like bottom-up estimating involve breaking down the project into smaller components for a more accurate estimate.

Commonly used cost estimation methods in the construction industry include:

1. Parametric Estimating

Parametric estimating involves using historical data and parameters to estimate costs based on specific project characteristics. This method is quick and useful for early-stage estimates.

2. Bottom-Up Estimating

Bottom-up estimating involves estimating costs for individual project components and then aggregating them to get the total project cost. This method is more detailed and accurate but requires more time and effort.

3. Analogous Estimating

Analogous estimating relies on past similar projects to estimate the cost of the current project. This method is useful when there is limited information available for the current project.

4. Three-Point Estimating, Cost estimation methods in construction industry

Three-point estimating involves estimating three scenarios for each cost item: optimistic, pessimistic, and most likely. This method helps in accounting for uncertainties and risks in the project cost estimation.

5. Vendor Bid Analysis

Vendor bid analysis involves obtaining cost estimates from vendors and contractors bidding for the project. This method can provide competitive pricing and insights into market rates.

6. Reserve Analysis

Reserve analysis involves setting aside contingency reserves to account for unforeseen circumstances or risks that may impact the project cost. This method helps in managing uncertainties and ensuring that the project remains within budget.

These are just a few examples of the cost estimation methods used in the construction industry to ensure accurate and reliable project cost estimates.

Types of Cost Estimation Methods

Cost estimation methods in the construction industry can vary based on different approaches and techniques. Here, we will explore the different types of cost estimation methods used in construction projects.

Top-Down vs. Bottom-Up Cost Estimation Approaches

Top-down and bottom-up are two common approaches to cost estimation in construction projects. Top-down estimation involves deriving an overall project cost based on historical data or expert judgment, while bottom-up estimation breaks down the project into smaller components and estimates the cost of each individual element.

- Advantages of Top-Down Estimation:

- Disadvantages of Top-Down Estimation:

- Advantages of Bottom-Up Estimation:

- Disadvantages of Bottom-Up Estimation:

Quick and easy to implement, especially in the early stages of a project. Provides a high-level overview of project costs.

May lack accuracy and detail, leading to potential cost overruns. Relies heavily on assumptions and may not account for all project variables.

Provides a detailed breakdown of project costs, making it easier to identify potential cost savings. Offers a more accurate estimate of project expenses.

Time-consuming and resource-intensive, especially for large and complex projects. Requires a thorough understanding of project scope and requirements.

Parametric Estimating in Construction Projects

Parametric estimating is a cost estimation method that uses statistical relationships between historical data and project parameters to calculate project costs. This approach is often used for repetitive or similar projects where historical data is readily available.

- Advantages of Parametric Estimating:

- Disadvantages of Parametric Estimating:

Can be more accurate than other estimation methods for projects with similar characteristics. Saves time by leveraging historical data and established relationships.

May not account for unique project variables or unforeseen circumstances. Relies heavily on the quality and relevance of historical data.

Analogous Estimating vs. Three-Point Estimating

Analogous estimating and three-point estimating are two commonly used techniques in cost estimation for construction projects. Analogous estimating relies on historical data from similar projects to estimate costs, while three-point estimating uses three estimates to determine a range of possible costs.

When starting out in programming, one of the first things you learn is the famous phrase ” Hello world! “. This simple message serves as a basic introduction to coding and is often the first program beginners write. It signifies the beginning of a journey into the world of programming and opens up a whole new realm of possibilities.

- Comparison of Analogous Estimating:

- Comparison of Three-Point Estimating:

Relies on expert judgment and historical data. Quick and easy to implement, but may lack accuracy for unique projects.

Provides a range of possible costs, accounting for uncertainties and risks. Requires more time and effort to calculate three estimates, but offers a more realistic cost estimate.

Factors Influencing Cost Estimation

Factors influencing cost estimation accuracy in construction projects are crucial for the successful completion of a project. The accuracy of cost estimation can significantly impact the overall project budget, timeline, and success. Several key factors influence cost estimation in construction projects, including project scope, design complexity, market conditions, historical data, and expert judgment.

Project Scope:

The project scope is a critical factor that influences cost estimation accuracy. A clear and well-defined project scope helps in identifying all the necessary resources, materials, labor, and other costs associated with the project. Changes in project scope can lead to cost overruns, delays, and inaccurate cost estimates. It is essential to have a thorough understanding of the project scope to ensure accurate cost estimation.

Design Complexity:

The complexity of the project design plays a significant role in cost estimation. Projects with intricate designs, unique architectural features, or specialized requirements may have higher construction costs. It is essential to consider the design complexity when estimating costs to account for any additional resources, materials, or labor required to execute the project successfully.

Market Conditions:

Market conditions, such as fluctuations in material prices, labor costs, and economic factors, can impact cost estimation accuracy. Changes in market conditions can affect the overall project budget and timeline. It is essential to stay updated on market trends and conditions to make informed decisions during the cost estimation process.

Role of Historical Data and Expert Judgment:

Historical data and expert judgment are valuable tools in refining cost estimates. Historical data from past projects can provide insights into similar projects, costs, and challenges that can help improve the accuracy of cost estimates. Expert judgment, based on experience and knowledge in the construction industry, can also play a vital role in refining cost estimates and identifying potential risks or opportunities for cost savings.

By considering these key factors influencing cost estimation accuracy in construction projects, project stakeholders can make informed decisions, mitigate risks, and ensure the successful completion of the project within budget and schedule constraints.

Technology and Innovation in Cost Estimation

Technology and innovation have significantly transformed the cost estimation process in the construction industry, leading to more accurate and efficient results.

Building Information Modeling (BIM) Software

Building Information Modeling (BIM) software plays a crucial role in enhancing cost estimation accuracy in construction projects. BIM allows for the creation of detailed 3D models that incorporate all relevant project information, including materials, quantities, and costs. By utilizing BIM software, project managers can generate more precise cost estimates by analyzing all project components in a comprehensive and integrated manner.

Impact of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning technologies have revolutionized cost estimation accuracy in the construction industry. These advanced technologies enable the automation of repetitive tasks, data analysis, and predictive modeling, resulting in more reliable cost estimates. AI and machine learning algorithms can process vast amounts of data to identify patterns and trends, leading to more informed decision-making and cost projections.

When it comes to programming, the first thing you learn is to print “Hello world!” on the screen. It’s a universal tradition for beginners in the coding world. If you want to know more about this iconic phrase, you can check out this interesting article on Hello world!.

Innovative Tools and Software

Several innovative tools and software applications have emerged to streamline and enhance cost estimation processes in construction. For example, cloud-based cost estimation platforms provide real-time collaboration and data sharing among project stakeholders, improving communication and reducing errors. Additionally, virtual reality (VR) and augmented reality (AR) tools allow project teams to visualize and interact with project designs, facilitating better cost estimation and decision-making.

Best Practices for Cost Estimation

When it comes to cost estimation in the construction industry, following best practices is crucial to ensure the success of a project. A comprehensive cost estimation plan, regular monitoring and control of costs, and strategies to mitigate risks and uncertainties are essential aspects to consider.

Developing a Comprehensive Cost Estimation Plan

- Start by creating a detailed project scope that Artikels all the requirements and deliverables.

- Break down the project into smaller tasks and estimate the cost for each task.

- Consider all possible factors that could impact costs, such as materials, labor, equipment, and overhead expenses.

- Use historical data and benchmarks to validate your estimates and adjust them accordingly.

Importance of Regular Cost Monitoring and Control

- Monitor costs throughout the project lifecycle to identify any deviations from the initial estimates.

- Implement a system to track expenses, analyze variances, and take corrective actions when necessary.

- Regularly communicate with stakeholders to keep them informed about the project budget and any cost changes.

Tips for Mitigating Cost Estimation Risks and Uncertainties

- Account for contingencies in your estimates to account for unexpected events or changes in the project scope.

- Engage with experienced contractors and suppliers to get accurate pricing and reduce the likelihood of cost overruns.

- Use advanced cost estimation software and tools to improve the accuracy of your estimates and streamline the process.

- Regularly review and update your cost estimation plan to reflect any changes in the project scope or market conditions.

Final Review: Cost Estimation Methods In Construction Industry

In conclusion, mastering cost estimation methods is essential for ensuring the success of construction projects. By adopting best practices, leveraging technology and innovation, and understanding the various factors at play, professionals in the construction industry can navigate the complexities of cost estimation with confidence.