Quality control procedures in construction projects play a crucial role in achieving success and maintaining safety standards. From minimizing errors to ensuring quality, these procedures are vital for project execution. Let’s delve deeper into this essential aspect of construction management.

Importance of Quality Control Procedures in Construction Projects

Quality control procedures play a crucial role in ensuring the success of construction projects by maintaining high standards of quality and safety throughout the project lifecycle. These procedures are essential for minimizing errors, rework, and ensuring compliance with project specifications and regulations.

Significance of Quality Control Procedures

Quality control procedures are instrumental in maintaining the overall quality and safety of construction projects. By implementing rigorous quality control measures, construction teams can identify and address any deviations from the project requirements early on, preventing costly errors and delays. This proactive approach helps in delivering projects that meet or exceed client expectations and industry standards.

- Quality control procedures help in detecting defects and deficiencies during the construction process, allowing for timely corrections and preventing issues from escalating.

- By adhering to quality control protocols, construction teams can ensure that materials and workmanship meet the specified standards, resulting in durable and long-lasting structures.

- Regular quality inspections and testing help in verifying the structural integrity and performance of construction components, enhancing the overall quality and safety of the finished project.

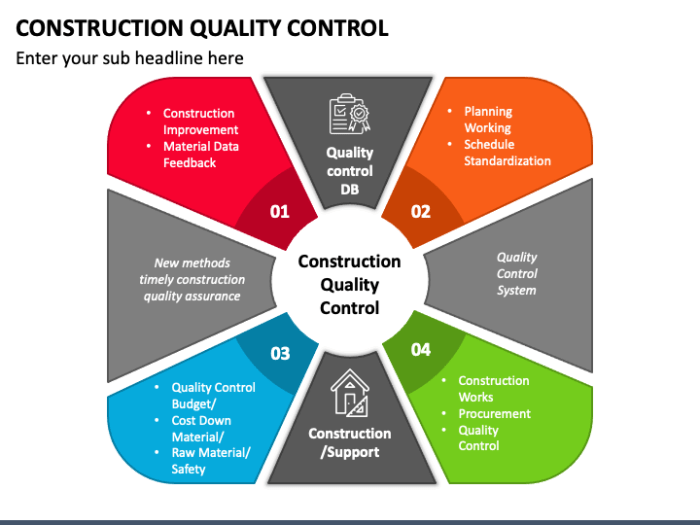

Key Elements of Quality Control Procedures

Quality control procedures in construction projects typically include the following key elements that are essential in ensuring that quality standards are maintained throughout the project:

1. Quality Planning, Quality control procedures in construction projects

Quality planning involves establishing objectives and requirements for the project, as well as developing a plan to meet those requirements. This includes defining quality criteria, setting quality targets, and determining the processes and resources needed to achieve them.

Example: Before starting construction, a project manager creates a quality management plan outlining quality objectives, roles and responsibilities, quality control measures, and quality assurance procedures.

2. Quality Assurance

Quality assurance focuses on preventing defects by implementing processes and procedures to ensure that work is done correctly the first time. This can involve regular inspections, testing, audits, and reviews to verify that quality standards are being met.

Example: A third-party quality assurance team conducts routine inspections of construction materials and workmanship to ensure compliance with building codes and project specifications.

3. Quality Control

Quality control involves monitoring and evaluating the construction process to identify and correct any deviations from quality standards. This includes implementing corrective actions, conducting quality checks, and documenting quality issues and resolutions.

Example: Inspectors on-site conduct daily inspections of work progress, materials, and installations to identify any quality issues and address them promptly.

4. Quality Improvement

Quality improvement focuses on continuously improving processes and procedures to enhance overall project quality. This can involve analyzing data, identifying trends, and implementing corrective actions to prevent future quality issues.

Example: After completing a project, the project team conducts a post-project review to identify areas for improvement and implement changes in future projects.

By incorporating these key elements into quality control procedures, construction projects can maintain high-quality standards, meet client expectations, and ensure the successful completion of the project.

Implementing Quality Control Procedures

Implementing quality control procedures in construction projects is crucial to ensure that the final outcome meets the required standards and specifications. It involves a series of steps to be followed diligently to maintain quality throughout the project.

When it comes to tackling a construction project, proper scheduling and planning are crucial for its success. A well-executed plan ensures that tasks are completed on time and within budget. For more insights on construction project scheduling and planning, you can visit Construction project scheduling and planning.

Steps Involved in Implementing Quality Control Procedures:

- Develop a Quality Control Plan: Create a detailed plan outlining the quality standards, inspection procedures, and responsibilities of each team member.

- Training and Education: Provide necessary training to the project team on quality control procedures and standards to ensure everyone is on the same page.

- Regular Inspections: Conduct regular inspections at various stages of the project to identify any deviations from the quality standards.

- Corrective Actions: Address any issues or non-conformities promptly by taking corrective actions to maintain quality.

- Documentation: Maintain detailed records of quality control activities, inspections, and corrective actions taken for future reference.

Challenges and How to Address Them:

- Lack of Awareness: Ensure that all team members are educated about the importance of quality control and provide necessary training.

- Resource Constraints: Allocate sufficient resources and manpower to implement quality control procedures effectively.

- Resistance to Change: Communicate the benefits of quality control to the team and stakeholders to overcome resistance.

Best Practices for Implementing and Monitoring Quality Control Procedures:

- Regular Communication: Maintain open communication channels to address any quality issues promptly.

- Continuous Improvement: Implement feedback mechanisms to continuously improve quality control processes.

- Quality Audits: Conduct regular quality audits to assess the effectiveness of the quality control procedures.

- Empower Team Members: Encourage team members to take ownership of quality control and empower them to make decisions.

Quality Control Tools and Technologies: Quality Control Procedures In Construction Projects

Quality control in construction projects has greatly benefited from the advancement of tools and technologies. These modern solutions have revolutionized the way quality is monitored and maintained throughout the project lifecycle.

Building Information Modeling (BIM)

Building Information Modeling (BIM) is a powerful technology that allows for the creation and management of digital representations of the physical and functional characteristics of a construction project. By utilizing BIM, project teams can collaborate more effectively, identify potential clashes early on, and ensure that the project is built according to specifications.

Drones for Aerial Inspections

Drones have become an essential tool for quality control in construction projects, especially for conducting aerial inspections. Drones can capture high-resolution images and videos of the construction site, providing valuable data for monitoring progress, identifying issues, and ensuring compliance with design plans.

Mobile Applications for Field Reporting

Mobile applications have transformed the way field reporting is done in construction projects. With the help of mobile apps, construction teams can easily record and report quality control data in real-time, improving communication, transparency, and efficiency on the job site.

Epilogue

In conclusion, quality control procedures are the cornerstone of successful construction projects. By implementing these procedures effectively and utilizing modern tools and technologies, project outcomes can be improved significantly. Stay vigilant, stay quality-conscious.

Project management plays a vital role in the construction industry. It helps in coordinating various activities, resources, and stakeholders to ensure the project’s smooth progress. If you want to delve deeper into the importance of project management in construction, check out Importance of project management in construction.