Kicking off with Construction safety guidelines for workers, this opening paragraph is designed to captivate and engage the readers, setting the tone formal and friendly language style that unfolds with each word.

Construction sites can be hazardous environments, making it crucial for workers to adhere to strict safety guidelines to prevent accidents and injuries. This article delves into essential safety protocols that construction workers need to follow to ensure their well-being and the well-being of others on site.

Overview of Construction Safety Guidelines for Workers

Construction safety guidelines have been developed over time to ensure the well-being of workers on construction sites. These guidelines aim to prevent accidents, injuries, and fatalities by outlining specific protocols and procedures to be followed.

It is crucial for workers to adhere to safety guidelines on construction sites to protect themselves and others from potential hazards. By following these guidelines, workers can minimize risks and create a safer working environment for everyone involved.

Importance of Following Safety Guidelines

Adhering to safety guidelines is essential in the construction industry to prevent accidents and injuries. Non-compliance with safety protocols can lead to severe consequences, including loss of life, injuries, and financial liabilities for workers and employers.

When it comes to programming, one of the first things you learn is the famous phrase “Hello world!”. It serves as a simple introduction to the world of coding. If you want to know more about the significance of this phrase, you can check out this interesting article on Hello world!.

Statistics show that a significant number of accidents and injuries in the construction industry are a result of non-compliance with safety guidelines. By prioritizing safety and following established protocols, workers can reduce the likelihood of accidents and create a safer work environment.

When it comes to programming, one of the first things you learn is how to display “Hello world!” on the screen. It’s a simple yet essential step in any coding journey. If you’re new to this concept, you can find a detailed guide on how to achieve this at Hello world!.

Personal Protective Equipment (PPE)

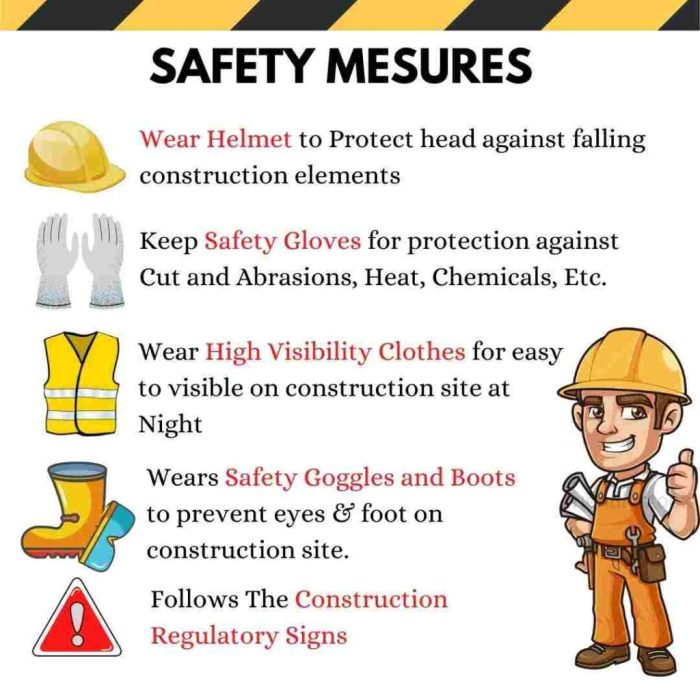

Personal Protective Equipment (PPE) is crucial for construction workers to ensure their safety on the job site. PPE includes various types of gear designed to protect workers from hazards and prevent injuries.

Common Types of PPE

- Hard hats: Protect the head from falling objects

- Safety glasses/goggles: Shield the eyes from flying debris or chemicals

- High-visibility vests: Ensure visibility on site to prevent accidents

- Gloves: Protect the hands from cuts, burns, or chemicals

- Steel-toed boots: Guard the feet from heavy objects or sharp materials

- Earplugs/earmuffs: Reduce noise exposure and prevent hearing damage

- Respirators: Filter out harmful particles or chemicals in the air

Importance of Wearing PPE

Wearing PPE on construction sites is essential to minimize the risk of injuries and accidents. It acts as a barrier between the worker and potential hazards, providing an extra layer of protection. Failure to wear PPE can result in severe injuries, permanent disabilities, or even fatalities.

Proper Usage and Maintenance of PPE

It is crucial for construction workers to properly use and maintain their PPE to ensure its effectiveness:

- Inspect PPE before each use for any signs of damage or wear.

- Follow manufacturer guidelines for proper fitting and adjustment.

- Clean and sanitize PPE regularly to prevent contamination.

- Store PPE in a clean, dry place away from direct sunlight or extreme temperatures.

- Replace any damaged or expired PPE immediately to maintain protection levels.

Hazard Communication

The proper communication of hazards in a construction site is crucial for ensuring the safety of workers. This involves identifying and informing workers about potential dangers so they can take the necessary precautions to avoid accidents and injuries.

Common Hazardous Materials

- Asbestos: Commonly found in older buildings and can cause serious respiratory issues when disturbed.

- Lead: Found in paint and pipes, exposure can lead to lead poisoning.

- Silica: Dust from concrete, brick, and other materials can cause lung disease.

- Chemicals: Various chemicals used in construction like solvents and adhesives can be harmful if not handled properly.

Recognizing and Responding to Hazardous Materials

- Training: Workers should receive proper training on how to identify hazardous materials and the appropriate response procedures.

- Labels: Hazardous materials should be clearly labeled to indicate the potential dangers they pose.

- SDS: Safety Data Sheets provide detailed information on hazardous materials, including handling precautions.

- Personal Protective Equipment (PPE): Workers should always wear the necessary PPE when handling hazardous materials.

Fall Protection

In the construction industry, fall protection is a critical aspect of ensuring the safety of workers who are often working at heights. Regulations and best practices have been put in place to minimize the risk of falls and protect workers from serious injuries or fatalities.

Regulations and Best Practices

- Regulations such as OSHA’s Fall Protection Standard require employers to provide fall protection systems for workers on construction sites.

- Best practices include conducting regular inspections of fall protection equipment, ensuring proper installation of guardrails, and using personal fall arrest systems when working at heights.

Examples of Fall Protection Systems

- Guardrails: These are physical barriers erected along the edges of elevated surfaces to prevent workers from accidentally falling.

- Safety Nets: Safety nets are installed under elevated work areas to catch workers in case of a fall.

- Fall Arrest Systems: These systems include harnesses, lanyards, and anchor points to arrest the fall of a worker and prevent them from hitting the ground.

Training Requirements, Construction safety guidelines for workers

- Workers must receive training on how to properly use and inspect fall protection equipment before working at heights.

- Training should cover hazard recognition, proper fitting of harnesses, inspection of equipment, and emergency procedures in case of a fall.

Scaffolding Safety

Proper scaffolding setup and maintenance are crucial for ensuring the safety of workers on construction sites. Scaffolding provides a platform for workers to perform tasks at heights, and any negligence in its setup or maintenance can result in serious accidents.

Inspection Procedures for Scaffolding

- Inspect scaffolding before each use to ensure it is structurally sound and free from defects.

- Check for any missing or damaged parts, such as guardrails, toe boards, and planks.

- Verify that the scaffolding is properly secured and stable on a level surface.

- Ensure that all access points are safely secured and that the scaffolding can support the intended load.

Risks of Improper Scaffolding Practices

- Collapsed scaffolding can result in falls from heights, leading to serious injuries or fatalities.

- Unstable scaffolding can cause workers to lose their balance and fall while performing tasks.

- Missing guardrails or toe boards can increase the risk of workers slipping or falling off the scaffolding.

- Failure to inspect scaffolding properly can result in unnoticed defects that may compromise the safety of workers.

Electrical Safety

Working safely around electricity on construction sites is crucial to prevent accidents and injuries. Electrical safety guidelines are put in place to protect workers from potential hazards and ensure a safe work environment.

Importance of Electrical Safety Training

Electrical safety training is essential for all workers on construction sites to understand the risks associated with working around electricity and how to mitigate them. Training helps workers identify potential electrical hazards, use proper safety measures, and respond effectively in case of an emergency.

Common Electrical Hazards in Construction

- Exposed wiring: Loose or damaged electrical wires can pose a significant risk of electrocution if touched.

- Overloaded circuits: Using multiple devices on a single circuit can lead to overheating and potential fires.

- Faulty equipment: Malfunctioning tools or equipment can cause electrical shocks or short circuits.

- Improper grounding: Lack of proper grounding increases the risk of electric shock for workers.

- Water exposure: Working with electricity near water sources can result in serious injuries or fatalities.

Summary

In conclusion, prioritizing construction safety guidelines for workers is paramount in reducing accidents and creating a secure work environment. By implementing the practices Artikeld in this article, construction workers can work effectively while minimizing risks and ensuring their safety.